By-Product Valorisation

Home / Our Technologies / By-Product Valorisation

Most producers and processors focus their efforts on their core product and market. Thereafter, it is a scramble to optimise crop utilisation and by-production valorisation. The mindset is reflected in the language we use. The Waste Food Directory defines waste as ‘any substance or object which the holder discards or intends or is required to discard’.1 For example, crop trash instead of crop residue or waste instead of by-product. The language implies there is zero value to be had. However, crop burning is discouraged or prohibited due to its contribution to air pollution and GHG emissions, and value has been found in reincorporating crop residue into the soil. For The Coca-Cola Company, which historically treated its orange pulp as waste from the orange juice process, a change in mindset was behind the product development of Minute Maid Pulpy Orange for the Chinese market. Minute Maid Pulpy Orange was their first billion-dollar brand after the iconic Coca-Cola.

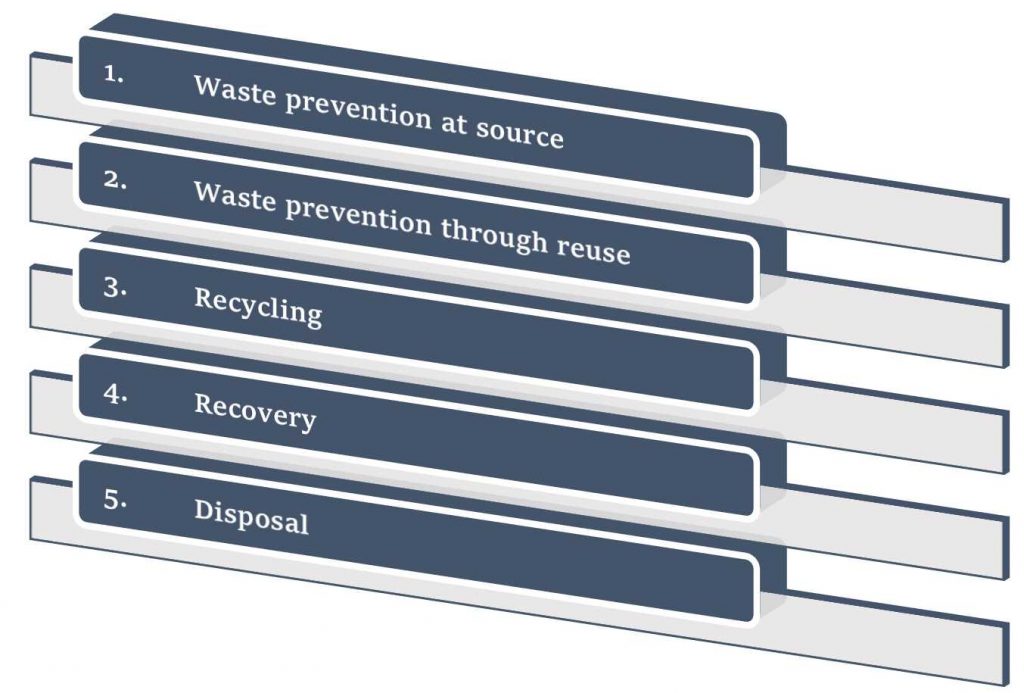

Most processors try to find a quick-fix solution for their by-products, typically low-value options including composting and animal feed. However, locked in these agricultural by-products are molecules with highly functional properties. European Policy has developed the food waste hierarchy, based on a five-tier principle (Metcalfe et al., 2017):

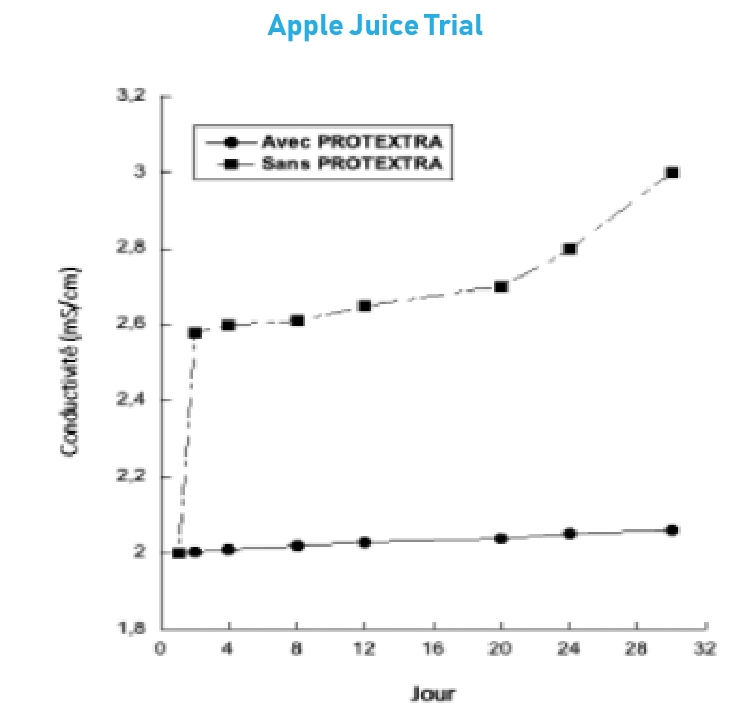

The use of Protextra® as an alternative to citric and ascorbic acid enhances quality, with the scope to reduce sugar content and extend shelf-life. The current reliance by the food and beverage sector on citric acid and ascorbic acid for food & beverage preservation has significant commercial limitations. The current commercial restrictions on shelf-life are driven by quality, not food safety. Protextra® can provide the following functional solutions:

- Step One

Low concentrations of Protextra® will decationise naturally-occurring pro-oxidant minerals like iron, copper, and aluminium. Electroconductivity is decreased and stabilised, preventing oxidation more effectively than ascorbic acid, allowing manufacturers to enhance sensorial quality, extend shelf-life, reduce wastage, and maintain vitamin C content. - Step Two

Increased concentrations of Protextra® will further drop the pH and act as a partial or complete substitute for citric acid. Food safety is achieved without the acidic, drying taste associated with citric acid. Benefits include reduced or eliminated need for sugar to mask the flavour of citric acid.

How does it work?

- Treatment of water used to wash food, i.e. fruit and vegetable salads, whole produce, and

- Added direct to liquid solutions.

Sliced Apple Trial

Photo day 0

Photo day 3 (with Protextra®)

Photographic evidence demonstrating how apple slices treated in Protextra® are stablished.

Technological and functional benefits

These benefits are realised by changing the pathway of acidification.

The main benefits of our innovative approach to food safety and quality for the food and beverage sector include:

- Quality enhancement,

- Clean label solutions,

- Reduced need for added sugar to mask flavour,

- Valorisation of by-products for agri-food processors, and

- Reduced wastage (climate and environment-friendly technological solutions).

Other molecules

In addition to Protextra®, other molecules have been retrieved and found to show antifungal properties:

Papaya Trial

Day 5 – Control vs Protextra®

Photographic evidence showing how green postharvest solutions can reduce chemical fungicides on many commercial fruit.

This exciting green technology is still in the product innovation phase.

Please CONTACT US for more information.

References

FAO (2021). The scourge of food loss and waste needs to be urgently tackled to achieve the world’s 2030 target.

FAO. Retrieved 02 December 2021 from https://www.fao.org/news/story/en/item/1441673/icode/

Mekonnen, M.M. & Hoekstra, A.Y. (2010). The green, blue and grey water footprint of farm animals and animal products. Value of Water Research Report Series No. 48, UNESCO-IHE, Delft, the Netherlands.

Metcalfe, P., Moates, G. & Waldron, K. (2017). Detailed hierarchy of valorisation approaches. REFRESH. Horizon 2020 Framework Programme of the European Union.

1 Article 3(1) Directive 2008/98/EC